Steel Sheet Coil Slitting Machine / Metal Sheet Cutting Production Line

1.Coil car

| Technical parameters: | |

| Bearing capacity | 10 tons |

| Mobile speed | 7 m/min |

| Mobile electric machine | 2.2KW |

2.Hydraulic uncoiler

| Technical parameters: | |

| Bearing capacity | 10 tons |

| Mandrel shrinkage | 50 mm (465~ 515mm) |

| The working pressure of the shrink cylinder | About 12MPa |

3.Feeding mechanism

| The working pressure of oil cylinder | About 12MPa |

4. Levelling machine

| Technical parameters: | |

| Leveling roller number | 5 |

| Number of feeding rolls | 2 |

| Leveling roller diameter | 110 mm |

| Leveling roller material: | 40Cr |

| Main motor power | 15 KW |

5.End cutting

| Technical parameters: | |

| Shear plate thickness | 0.5 - 3mm |

| Shear plate width | 1250 mm |

6.Correction mechanism

| Centering range | 600 ~ 1250mm |

7.Slitting Machine

| Technical parameters: | |

| Diameter of cutter shaft | 200mm |

| Outer diameter of cutterhead | 300mm |

| Blade material | H13 |

| Cutter shaft material | 40Cr |

| Main motor power | 75 kW |

8.Waste edge winder

| Width of waste side | 5-15mm |

9.Winder

| Technical parameters: | |

| Winding machine load | 10 T |

| Mandrel shrinkage | 30mm |

| The mandrel's shrink range | 508mm. |

| Motor power | 90KW |

10.Discharging car

| Technical parameters: | |

| Bearing capacity | 10 tons |

| Mobile speed | 7 m/min |

| Mobile motor power | 2.2 kw |

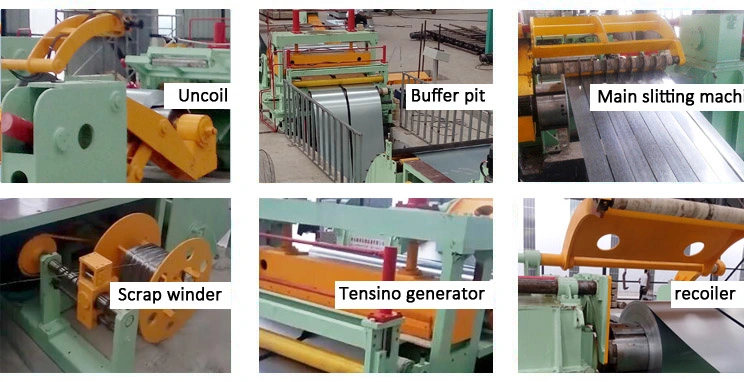

Main Equipments

1. coil car

2. decoiler

3. peeler entry table

4. Straightener

5. Shearing machine

6. loop table

7. coil guide and pinch roll

8. Slitting machine

9. scrap winder (both sides)

10. Loop table

11. separator and tension table

12. Deflector roll and exit threading table

13. Recoiler

14. Over arm separator in the recoiler.

15. Exit coil car for recoiler

16. Hydraulic system

17. pneumatic system

18. electrical control system

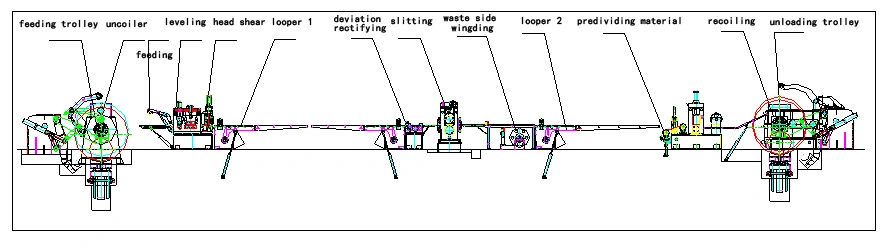

Flow Chart

Our Service

* One year free warranty.

* Follow-up project automation upgrading.

* Technical support.

* Be customized according to client's requirments.

FAQ

Q: Can your machine be customized ?

A: Yes, we are a professional manufacturer specialized in automatic welding